As VOCs represent a serious health and environmental hazard, their release is strictly regulated by law. Manufacturers must also control evaporation losses, as their products can otherwise literally vanish into thin air.

VOC emission control with CIRRUS® VEC

CIRRUS vapour emission control (VEC) is a modular, flexible, compact and efficient waste gas treatment solution.

Key advantages

- Minimising the release of VOCs into the atmosphere

- Recovering valuable VOCs to save costs

- Efficient use of nitrogen, since it can be used twice:

- Cryogenic cooling with liquid nitrogen for VOC emission control

- Inerting with the gaseous nitrogen that exits the cryogenic cooling process

- Supporting all sizes or configurations thanks to modular design

VOC recovery with CIRRUS

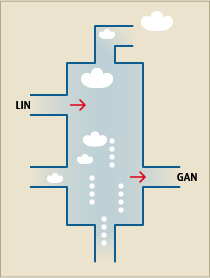

Cryogenic condensation of VOC loaded off-gas streams with liquid nitrogen is an ideal way to efficiently condense VOCs and capture them so they can be routed back into the process or further treated.

CIRRUS portfolio - flexible design

We offer a wide range of complete cryogenic solutions.

- CIRRUS VEC comes in three different sizes (handling flow rates up to 1000 Nm³/h) to ensure the perfect fit for your needs and comprises a pre-condenser for the biggest unit (M500).

- The CIRRUS VEC system can be easily expanded by simply adding a new module.

- It is suited to both batch and continuous processing applications.

- To ensure fast deployment, each CIRRUS VEC module features its own control system and is delivered pre-assembled and pre-tested.

- A broad operating range also allows greater flexibility to adapt quickly to changing plant conditions.

- Emission levels can be reduced by lowering the condensation temperature setpoint.

- The units comply with all relevant EU and US regulations.

Pre-Condenser (PC500)

During cryogenic condensation, freezing can occur inside the main cryogenic condenser. Depending on the specific VOC mixture, this can be caused by the high freezing temperature of certain VOCs or a high level of water vapour. This freezing impacts process efficiency as it lowers the operation time of the cryogenic condensation unit(s) and increases the time needed to defrost them.

The PC500 pre-condenser is an upstream option for our CIRRUS® M500 VEC system portfolio and provides an extended operating window for the complete system. It eliminates high freezers and water and also reduces process temperatures to as low as –30°C (–22°F).

The main benefits of using our pre-condenser are:

- Provides a safe and uninterrupted operation of the whole setup.

- Presents a potential to save money by increasing the run time of the main units.

- Allows for nitrogen re-use in other processes such as inerting and blanketing.

- Lower OPEX and CAPEX compared to alternative technologies.

Our service and support

We support all steps in the project management cycle, from planning to installation and start-up. We also offer gas supply and after-sales support. In addition, customers have the option of participating in test runs at our pilot plant or conducting trials at their own site.

All units are available for short-term test rentals. Our equipment pool comprises at least one unit of each size.